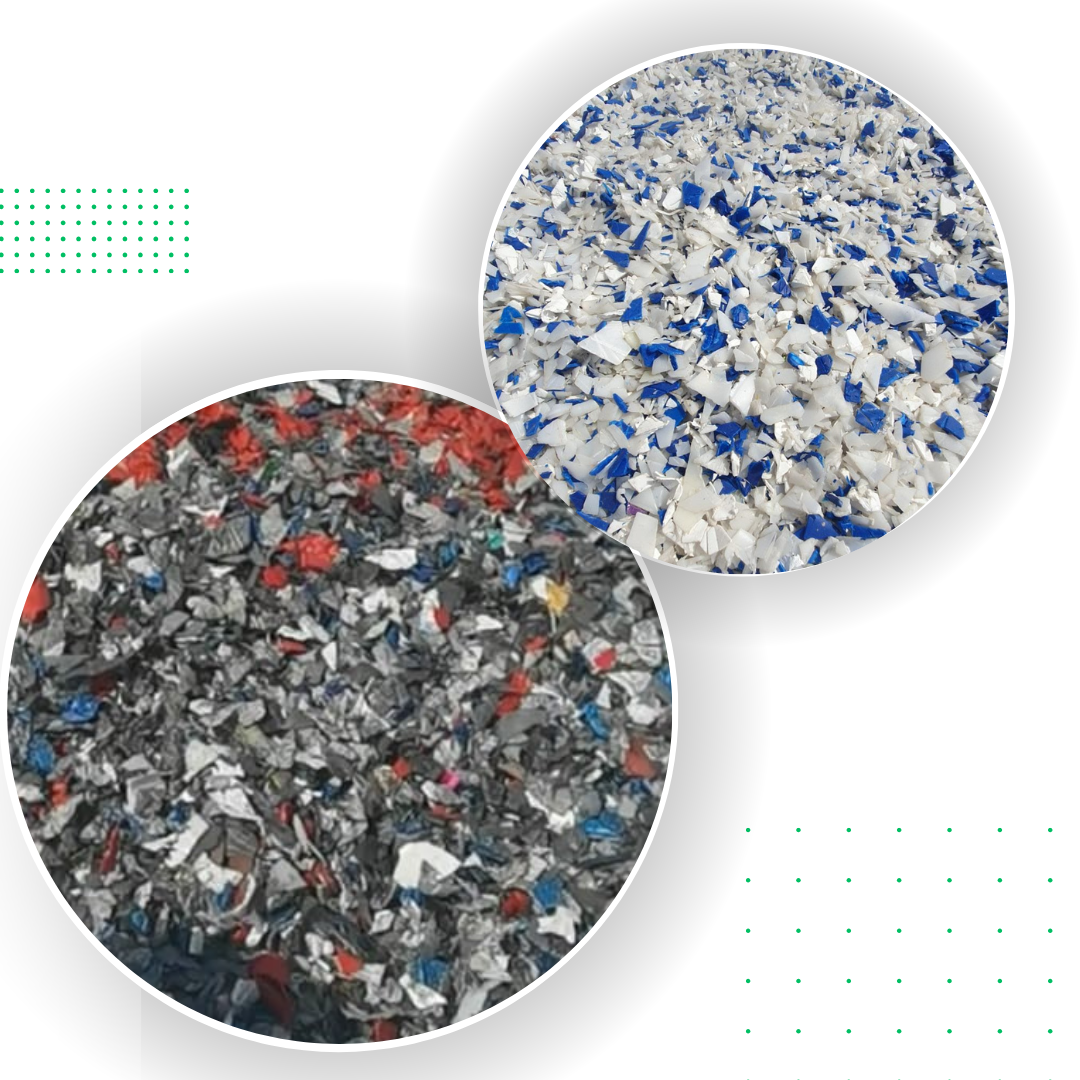

HDPE Blow Grade Regrinds / Flakes

HDPE is a versatile plastic utilized throughout sectors. HDPE blast grade resin is designed for blow molding. These materials are essential for making lightweight, robust bottles, containers, and industrial drums. With the focus on recycling and sustainability, HDPE blow grade regrinds and flakes are becoming eco-friendly alternatives to virgin resins.

What Are HDPE Blow Grade Regrinds and Flakes?

HDPE blow-grade regrinds and flakes are recycled from post-consumer or industrial HDPE. "Regrinds" are shredded or ground plastic, whereas "flakes" are flat recycled fragments. These materials preserve HDPE blow grade resin characteristics, making them perfect for reprocessing into new products without compromising quality.

Regrinds and flakes are sorted, cleaned, and treated to satisfy reuse specifications. To balance cost and performance, manufacturers combine these materials with virgin HDPE.

Manufacturing Process of HDPE Blow Grade Regrinds

The production of HDPE blow grade regrinds and flakes involves several critical steps:

1. Collection and Sorting: Waste HDPE products are collected and sorted based on resin type, color, and cleanliness.

2. Cleaning: Advanced washing systems remove contaminants like labels, adhesives, and residue.

3. Shredding: HDPE waste is shredded into smaller pieces, forming regrinds.

4. Flaking: Shredded materials are further processed into flakes, ensuring consistent size and shape.

5. Quality Control: The regrinds and flakes are tested for purity, density, and melt flow index to ensure they meet the required specifications.

By following this meticulous process, manufacturers can produce high-quality HDPE blow grade regrinds and flakes suitable for diverse applications.

Key Properties of HDPE Blow Grade Materials

HDPE blow grade materials, including regrinds and flakes, offer several key properties:

- High Strength-to-Weight Ratio: Lightweight yet durable, making them ideal for industrial and consumer goods.

- Chemical Resistance: Resistant to many chemicals, ensuring longevity in harsh environments.

- Flexibility: Retains shape and structure even under pressure, a vital property for blow-molded products.

- Recyclability: Easily recyclable, contributing to reduced waste and a circular economy.

These properties make HDPE blow grade regrinds and flakes indispensable in various industries.

- HDPE Blow Grade - Products

Benefits of Using HDPE Blow Grade Regrinds and Flakes

Using HDPE blow grade regrinds and flakes offers multiple advantages:

- Related Products

HIPS Recycled Flakes UAE – Cost-Effective Raw Material for Industrial

PPCP Regrind Supplier in Sharjah, UAE Our premium PPCP Regrind

PPR Green Plastics Granules in UAE: High-Performance, Sustainable, and Industry-Ready

PP Silver Plastic Granules in UAE: Properties, Applications & Market

Black Polypropylene Granules: High-Performance Material for Industrial Applications When it

PP Fruit Crates Regrind: A Sustainable Solution for Your Packaging

Soft PVC Cable Grade Regrind Soft PVC Cable Regrind Grade

Introduction - ABS Fridge Sheet Regrinds Acrylonitrile Butadiene Styrene—ABS Fridge Sheet

ABS Batteries Regrind: High-Quality, Sustainable & Cost-Efficient Material in Sharjah

[…] ABS Batteries Regrind […]

[…] ABS Batteries Regrind […]

[…] ABS Batteries Regrind […]

[…] ABS Batteries Regrind […]

[…] ABS Batteries Regrind […]

[…] ABS Batteries Regrind […]

[…] ABS Batteries Regrind […]

[…] ABS Batteries Regrind […]

[…] ABS Batteries Regrind […]

[…] ABS Batteries Regrind […]